Core role

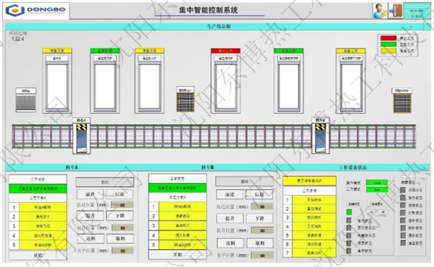

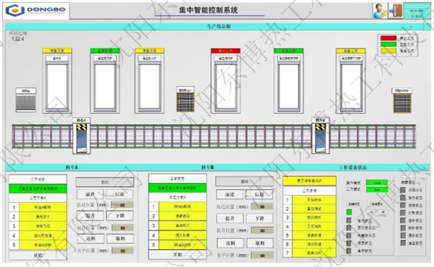

The main functions of the process control system (PCS) of various types of equipment produced by our company are as follows:

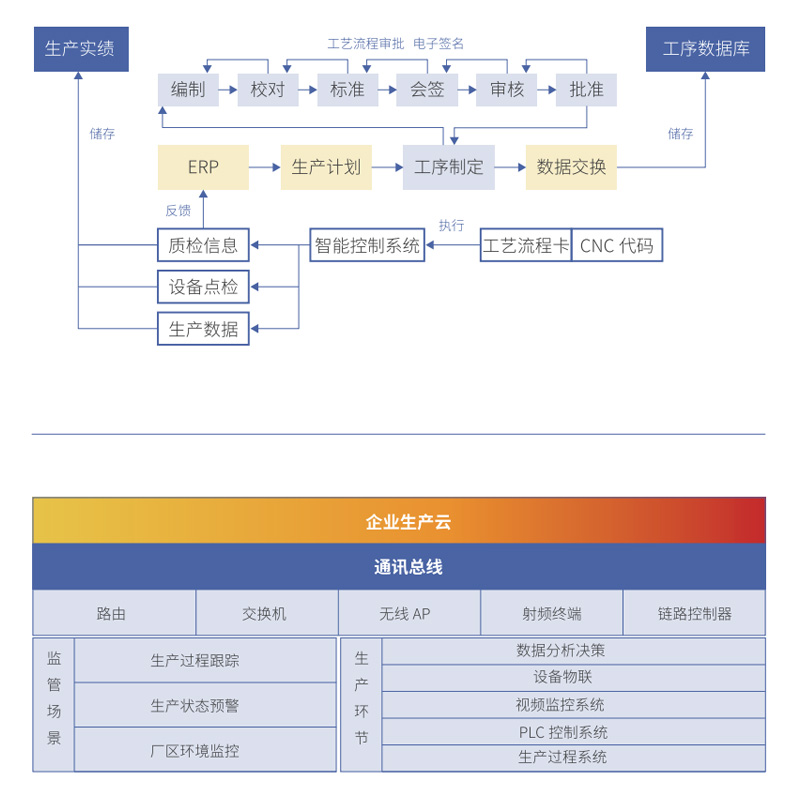

1. Production process management: automatically select the process parameters required for processing according to the material information;

2. Production process tracking: feed back and record production process data in real time, including equipment operation status, workpiece processing status, etc;

3. Historical trend data: record real-time data such as temperature, vacuum degree and water pressure in milliseconds, and support trend information query and report export at any time within 10 years;

4. Work and material quality defect report (QDR): generate QDR based on the basic information of work and material and the measured data of equipment, and summarize and evaluate the processing quality of work and material;

5. System offline maintenance function: support system offline update and upgrade.

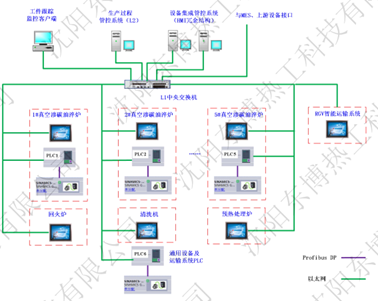

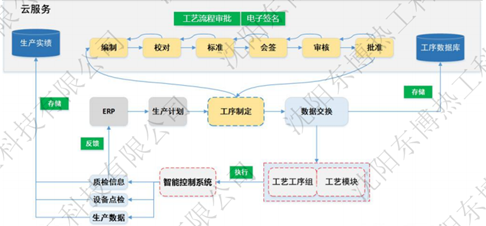

The distributed control system (DCS) of various vacuum heat treatment production lines produced by our company has the following main functions:

1. Have all functions of PCS system of single equipment;

2. Process flow management: provide process management for process formulation, approval, distribution, implementation and other steps;

3. Intelligent production scheduling: according to the equipment status of the production line and the status of the materials to be processed and other information, provide the intelligent scheduling function with time priority and energy consumption priority to improve the equipment utilization and production efficiency;

4. Smart Kanban: equipment operation status, workpiece processing execution status, power consumption, energy consumption, etc. are displayed in real-time in the form of dynamic charts, supporting synchronous push of data on PC and mobile terminals;

5. Mobile console: the operation control system supports the data synchronization control of the mobile terminal, and the main function operations can be completed through mobile devices;

6. General data communication bus: compatible with all mainstream communication protocols, seamless connection with the original equipment system, and barrier free data communication;

7. Data analysis and fault prediction: With big data analysis and artificial intelligence, equipment faults can be predicted according to the statistical analysis of historical data; At the same time, according to historical experience, optimize production control process and improve production efficiency.

The control system of vacuum thermal equipment&production line has been upgraded to be compatible with the original production mode and operation process. The process expert system has been upgraded and deployed, which can effectively improve the equipment control accuracy, workpiece processing quality and production stability.

Please consult Shenyang Dongbo for more detailed information or materials about the vacuum thermal equipment and its intelligent centralized control system of the production line:13130218123 // 18602471394