Vacuum quenching series equipment includes seven categories: 5.1

horizontal double chamber oil quenching type, 5.2 vertical double

chamber oil quenching type, 5.3 horizontal double chamber gas quenching

type, 5.4 horizontal single chamber gas quenching type, 5.5 vertical

single chamber gas quenching type, 5.6 horizontal double chamber water

quenching type, 5.7 vertical double chamber water quenching type;

Main applications of vacuum quenching furnace:

It

is mainly used to cool the heated metal materials under vacuum or inert

gas. The medium used for quenching is high-purity inert gas injected

after vacuumizing, as well as vacuum quenching oil and water-based

solvent. The vacuum quenching furnace can also realize the molding,

surface finish treatment, precipitation hardening, vacuum annealing and

other processes of high-speed steel and other steels.

Main advantages of vacuum quenching furnace:

Safety and environmental protection;

Good production flexibility, can stop and open the furnace at any time;

The surface quality of the workpiece is good, and the processing deformation is small;

High degree of equipment automation;

Low equipment maintenance cost.

Process control of vacuum quenching furnace:

Under

vacuum and inert gas protection, the quenching process realized in

conventional quenching furnace is completed in a fully automatic manner.

Vacuum quenching production line:

The

skip car system can be configured to form a production line with

multiple vacuum quenching furnaces, vacuum tempering furnaces, various

cleaning machines and other equipment to meet the production needs of

mass quenching.

Examples of photos of various types of equipment of vacuum quenching furnace are as follows:

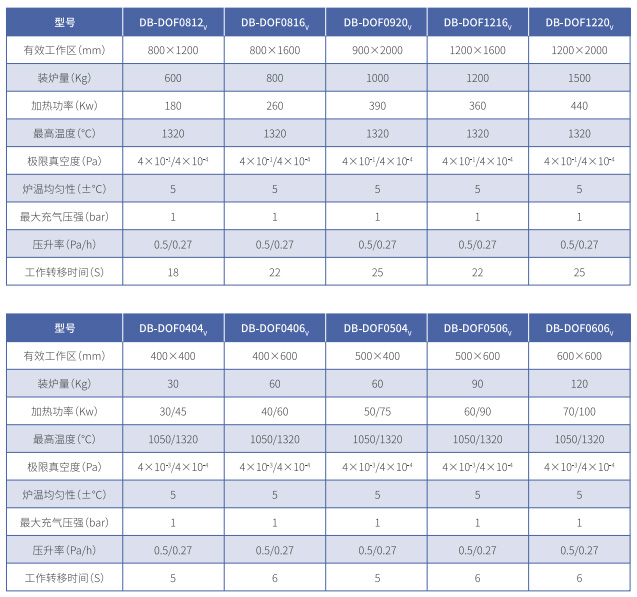

Take the category "5.2 vertical double chamber oil quenching type, 5.7 vertical double chamber water quenching type" as an example to list the main parameters of the current standard model equipment

Note:

The above are the parameters of our standard equipment.

Shenyang Dongbo can carry out non-standard design and manufacturing

according to the specific requirements of customers to meet their

personalized needs. For example, the extreme vacuum degree can reach

10-4Pa or above, and the pressure rise rate can be better than 0.1Pa/h.

For more detailed information or data on the main parameters, structures and processes of all types of equipment of Dongbo Thermal Engineering, please consult Shenyang Dongbo:13130218123 // 18602471394