The vacuum sintering series equipment includes four categories: 9.1

horizontal double chamber type, 9.2 horizontal single chamber type, 9.3

horizontal single chamber dewaxing type, 9.4 horizontal single chamber

pressure type;

Main purposes of vacuum sintering furnace:

It

is widely used in scientific research units, military industrial units

and other units, mainly for the sintering and processing of tungsten

wire and other materials with high melting point, such as hard alloy,

which are difficult to melt and knot under vacuum state and environment;

Before using the vacuum sintering furnace, the water tank of the

external circulating water cooling system must be filled with little and

no impurities to ensure the safe operation of the vacuum sintering

furnace.

Main advantages of vacuum sintering furnace:

Safety and environmental protection;

Good production flexibility, can stop and open the furnace at any time;

The surface quality of the workpiece is good, and the processing deformation is small;

High degree of equipment automation;

Low equipment maintenance cost.

Process control of vacuum sintering furnace:

Because

of vacuum sintering, it is easy to control the carbon content of the

alloy; It can improve the purity of cemented carbide; There are few

impurities adsorbed on the surface of the hard phase, improving the

wettability of the drill to the hard phase, and improving the strength

of the alloy, especially the alloy containing TiC; The process is easy

to operate. It can realize dewaxing sintering integration, reduce

product oxidation, and reduce the difficulty of carbon control; Reduce

the occupied area and labor intensity. It can realize the integration of

multi atmosphere dewaxing and sintering, control the temperature,

atmosphere and furnace pressure respectively by temperature section,

achieve isothermal sintering (heat preservation) at any temperature, and

complete various functions, such as gradient alloy sintering.

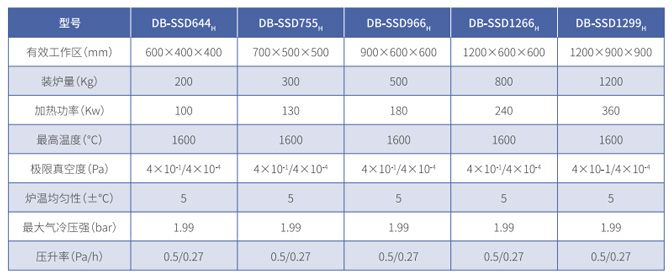

The vacuum sintering series equipment takes the category "9.3 horizontal single chamber dewaxing type" as an example to list the main parameters of the current standard type equipment

Note:

The above are the parameters of our standard equipment.

Shenyang Dongbo can carry out non-standard design and manufacturing

according to the specific requirements of customers to meet the

customer's personalized needs. For example, the extreme vacuum degree

can reach 10-4Pa or above; The pressure rise rate can be better than

0.1Pa/h, etc.

For more detailed information or data on the main parameters, structures and processes of all types of equipment of Dongbo Thermal Engineering, please consult Shenyang Dongbo:13130218123 // 18602471394