Vacuum metallizing series equipment includes two categories: 3.1 horizontal single chamber aluminizing type and 3.2 vertical single chamber aluminizing type;

Main purposes of vacuum metallizing furnace:

Vacuum aluminizing furnace is used to place metal elements on the surface of metal workpieces, and inject metal elements into metal workpieces through aluminizing technology and heat treatment technology. This element is used to treat metal molecules. Only metal molecules with a certain size can be injected into metal workpieces to improve the corrosion resistance of workpieces.

Main advantages of vacuum metallizing furnace:

Safety and environmental protection;

Low equipment maintenance cost. Process control of vacuum metallizing furnace:

Under vacuum and inert gas protection, the metallizing process realized on conventional metallizing equipment is completed in a fully automatic manner.

Examples of photos of various types of equipment in vacuum metallizing furnace are as follows:

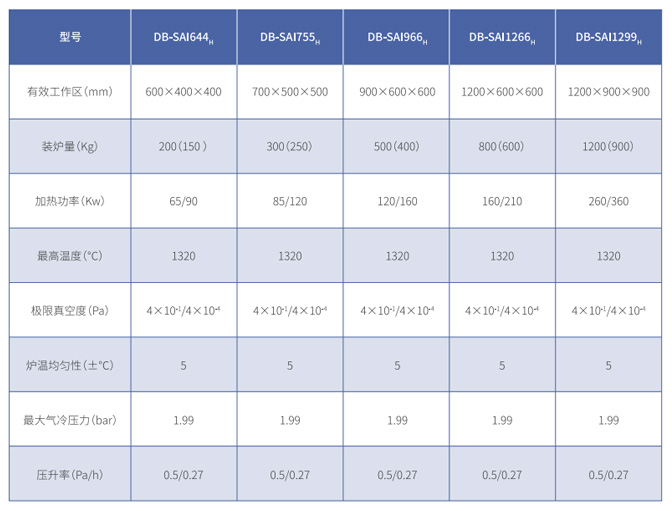

The vacuum metallizing series equipment takes the category "3.1 horizontal single chamber aluminizing type" as an example, and lists the main parameters of the current standard model equipment

Note:

The above are the parameters of our standard equipment. Shenyang Dongbo can carry out non-standard design and manufacturing according to the specific requirements of customers to meet their personalized needs. For example, the extreme vacuum degree can reach 10-4Pa or above, and the pressure rise rate can be better than 0.1Pa/h.

For more detailed information or data on the main parameters, structures and processes of all types of equipment of Dongbo Thermal Engineering, please consult Shenyang Dongbo:13130218123 // 18602471394