The vacuum hydrogen series equipment includes three categories: 10.1

horizontal double chamber air-cooled type, 10.2 horizontal single

chamber air-cooled type, 10.3 vertical single chamber air-cooled type;

Main purposes of vacuum hydrogen furnace:

It

is mainly applicable to the vacuum high-temperature brazing, vacuum

aging, hydrogen reduction, vacuum sintering and other heat treatment

processes of various materials such as high-speed steel, high alloy tool

and die steel, carburized steel, precision bearings, oil pump and

nozzle mechanical parts, precision machine parts, as well as the

sintering heat treatment processes of non-ferrous metals and magnetic

materials filled with hydrogen.

Main advantages of vacuum hydrogen furnace:

Environmental protection, cleaning, safety, no smoke, no explosion hazard, and less heat dissipation of cold furnace wall;

Large charging capacity and high degree of automation;

The furnace liner has less heat storage, and the furnace can be opened/shut down quickly;

Short process time, energy saving and high productivity;

The surface quality of the workpiece is good, and the heat treatment deformation is small;

Low equipment maintenance cost.

Process control of vacuum hydrogen furnace:

Under

negative pressure, we can adopt the proprietary technology process of

pulse gas filling (hydrogen) and negative pressure dynamic constant

pressure gas filling (hydrogen) to realize the reduction, brazing,

sintering, aging and other processes under hydrogen, which can save the

origin and ensure safety.

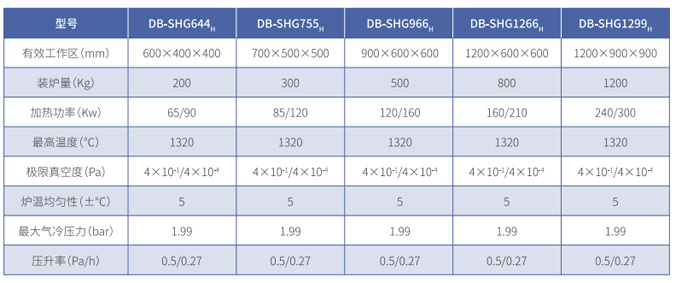

The vacuum hydrogen series equipment takes the category "10.2 horizontal single chamber air-cooled type" as an example to list the main parameters of its current standard model equipment

Note:

The above are the parameters of our standard equipment.

Shenyang Dongbo can carry out non-standard design and manufacturing

according to the specific requirements of customers to meet their

personalized needs. For example, the extreme vacuum degree can reach

10-4Pa or above, and the pressure rise rate can be better than 0.1Pa/h.

For more

detailed information or data on the main parameters, structures and

processes of all types of equipment of Dongbo Thermal Engineering,

please consult Shenyang Dongbo:13130218123 // 18602471394